Understanding Graphite Electrodes: Essential Components in Moder

Graphite electrodes are vital components in various industrial applications, playing a crucial role in electric arc furnaces (EAF) for steel production, the smelting of silicon metal, and other high-temperature processes. Their unique properties, such as excellent electrical conductivity, high thermal resistance, and the ability to withstand extreme temperatures, make them indispensable in these demanding environments.

What Are Graphite Electrodes?

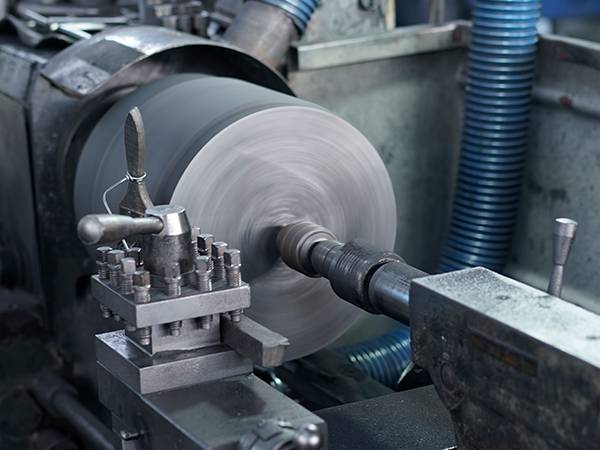

Graphite electrodes are cylindrical rods composed primarily of graphite, a form of carbon with an ordered atomic structure. They are manufactured through a meticulous process that involves mixing petroleum coke with a binding agent, followed by baking, graphitization, and machining to achieve the desired size and shape. The result is a material that offers superior performance in high-temperature, high-current environments.

Applications of Graphite Electrodes

·Steel Production in Electric Arc Furnaces (EAF):

The primary use of graphite electrodes is in electric arc furnaces for steelmaking. Here, they serve as conductors of electricity to generate the high temperatures required to melt scrap metal and produce steel. The use of EAFs is growing globally due to their energy efficiency and lower environmental impact compared to traditional blast furnaces.·Silicon Metal Production:

Graphite electrodes are also essential in the production of silicon metal, a key component in the manufacturing of solar cells, semiconductors, and silicones. The electrodes are used to conduct the necessary electricity to sustain the intense heat required for smelting quartz and carbon to produce silicon.

Other Applications:

Beyond steel and silicon, graphite electrodes are employed in the production of ferroalloys, aluminum, and various other metals. Their stability at high temperatures also makes them suitable for use in chemical processes, where resistance to oxidation and chemical erosion is critical.

Advantages of Graphite Electrodes

·High Electrical Conductivity: Graphite's structure allows for the free movement of electrons, making it an excellent conductor of electricity, essential for applications requiring high current densities.

·Thermal Stability: Graphite electrodes can withstand extreme temperatures without melting or degrading, making them ideal for use in processes involving intense heat.

·Resistance to Chemical Attack: The chemical inertness of graphite allows these electrodes to endure corrosive environments, extending their lifespan and reducing maintenance costs.

Challenges and Innovations

While graphite electrodes are highly effective, they are not without challenges. The rising cost of raw materials, particularly needle coke used in their production, has led to increased prices and supply shortages. Additionally, the environmental impact of graphite production is a concern, with efforts underway to develop more sustainable manufacturing processes.

Innovations in the field are focused on improving the efficiency and longevity of graphite electrodes. Research is being conducted to enhance their thermal and mechanical properties, reduce energy consumption during production, and develop recycling methods for used electrodes.

Conclusion

Graphite electrodes are a cornerstone of modern industry, enabling the production of steel, silicon, and various other materials crucial to the global economy. As the demand for cleaner, more efficient manufacturing processes grows, the importance of graphite electrodes will only increase. Understanding their role and the ongoing innovations in their production is essential for anyone involved in industrial manufacturing.